Services

|

| |

|

|

| |

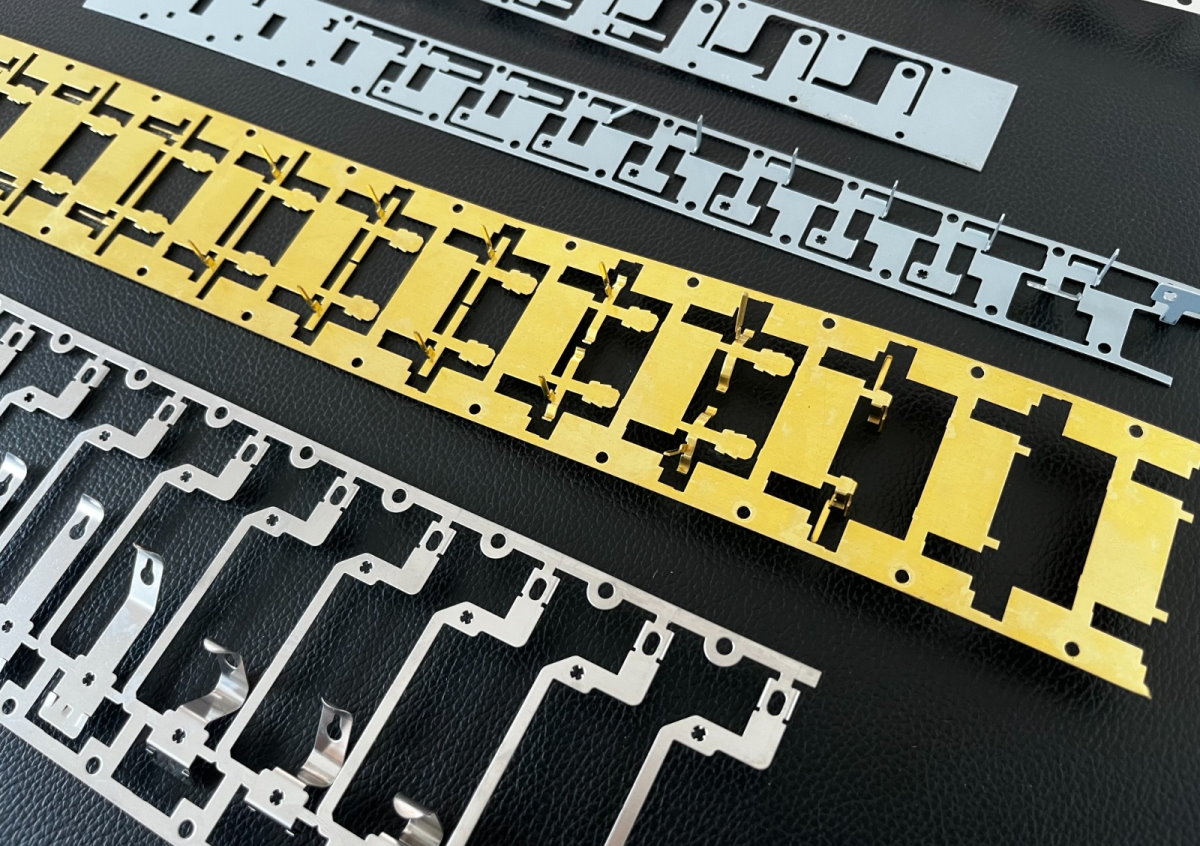

Metal Stamping & Production

|

|

|

| Our press machine capacity ranges between 16 tonnes to 150 tonnes. We have the capacity and versatility to handle job scale from high volume progressive die stamping to manual precision die stamping based on customers’ requirements and specifications. |

| |

| Apart from that we also provide secondary operations including tapping, cleaning, hardening, and platting process, with approved and trusted suppliers with consistent standards and quality. |

|

|

|

|

Mould Design & Drawing

|

|

|

| Discover the heart of precision in our Mould Design and Drawing section. Our skilled team is highly proficient in AutoCAD software, we are here to transforms concepts into reality, we design custom moulds including Manual Precision and Progressive moulds. With a commitment to precision and innovation, we collaborate closely to refine designs and deliver unmatched quality. |

|

|

|

Products

|

|

|

| We manufacture parts from a wide range of materials including galvanized steel, copper, brass, aluminum, stainless steel, etc. Material thicknesses range from 0.3mm to 3.0mm and above. And we have more than 20 years of experience in manufacturing metal parts for automotive, electronics & appliances, air-conditioning, & other industries. |

|

|

|

Repair & Maintenance

|

|

|

| We have dedicated mould engineers that provide Mould Repair and Maintenance services, where precision meets restoration. Our skilled team excels in repairing and maintaining moulds, breathing new life into worn tools and ensuring seamless production. With a collaborative approach, we diagnose, repair, and extend the lifespan of your moulds. From preventive care to precision restoration, experience reliability restored and efficiency maintained, to ensure good production quality. |

|

|

.jpg) |

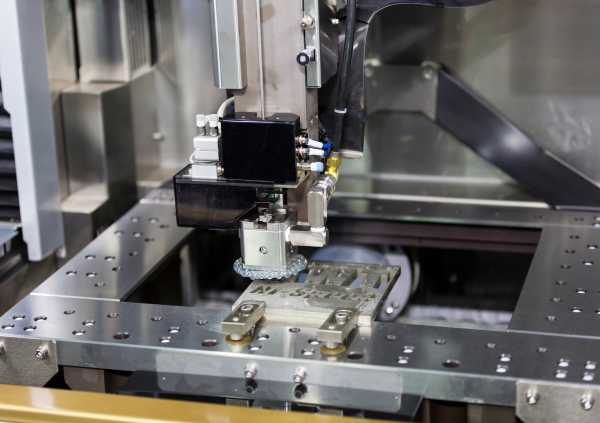

Quality Control

|

|

|

| Our quality inspector / engineer provides precision checking to ensure our products meet high standards and rules, and customer satisfaction. We always strive for continuous improvement to give you the best. |

| |

| We have various quality control equipment including vernier caliper, pin gauge, height gauge, measuring profile projector, and weighing machine. And we are planning to invest in more advance and up-to-date machines and technology to further improve the overall quality and efficiency. |

|

|

|

|